In the intricate world of car modeling and restoration, achieving absolute precision is paramount. For professionals and enthusiasts alike, the beam profile gauge tool emerges as an indispensable asset. This specialized instrument is engineered to meticulously measure and analyze the contours and dimensions of beams, playing a critical role in ensuring the structural integrity and aesthetic perfection of automotive projects.

What exactly is a beam profile gauge tool in the context of car modeling? It’s a precision instrument designed to accurately capture the profile of structural beams, frame rails, and chassis components of a vehicle. Unlike standard measuring tools, a beam profile gauge tool is specifically crafted to handle the complex shapes and angles inherent in automotive frames. This allows for precise assessments of straightness, curvature, and any deviations from the original specifications.

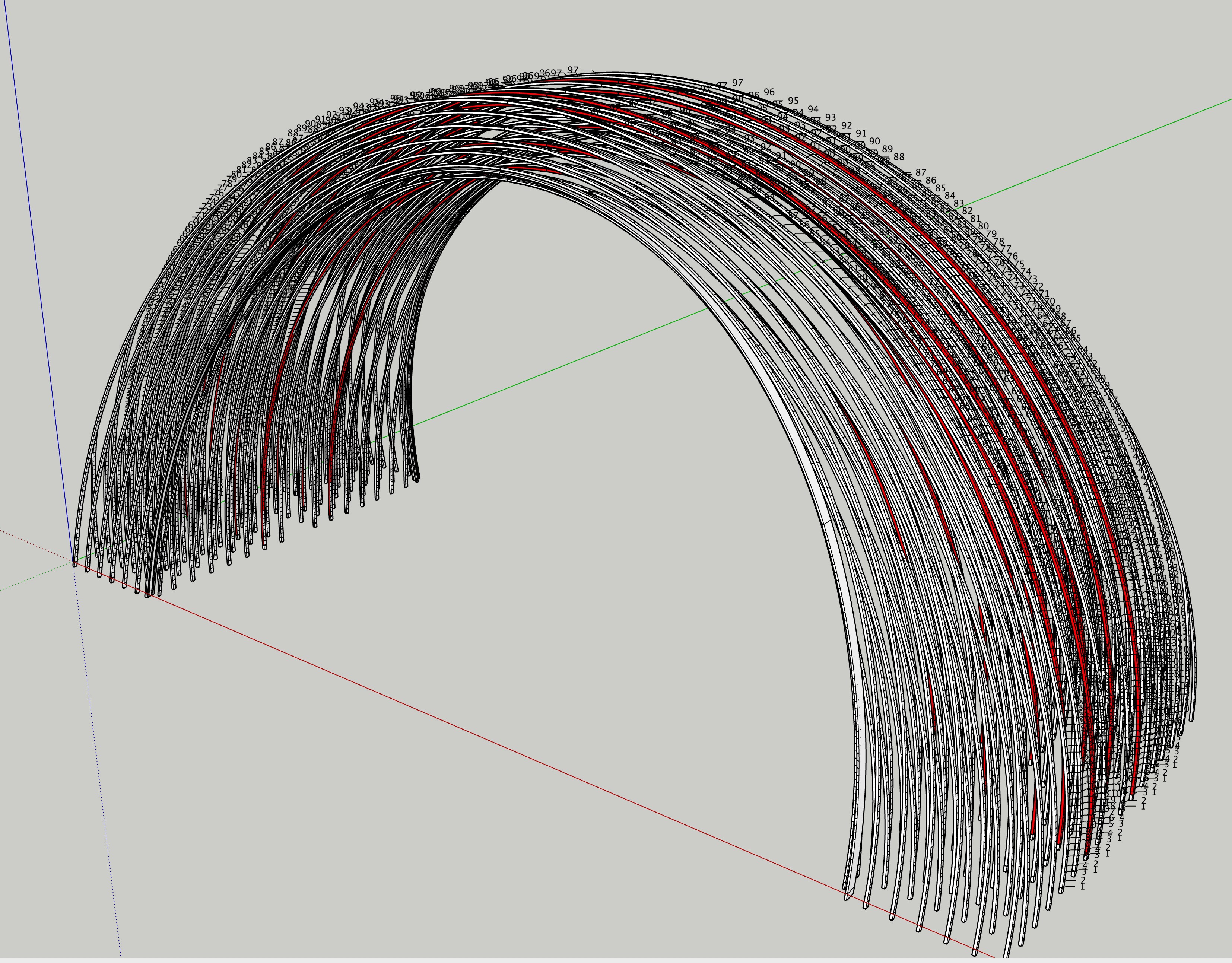

Structural columns ensuring robust framework, concept applicable to car chassis integrity and dimensional accuracy using beam profile gauge tools.

Structural columns ensuring robust framework, concept applicable to car chassis integrity and dimensional accuracy using beam profile gauge tools.

The benefits of incorporating a beam profile gauge tool into your car modeling or repair workflow are manifold. Firstly, accuracy is significantly enhanced. These tools provide highly precise measurements, minimizing errors and ensuring that restorations or modifications adhere to exact specifications. This accuracy is crucial when dealing with chassis alignment and frame repairs, where even minor discrepancies can impact vehicle safety and performance.

Secondly, efficiency is greatly improved. Beam profile gauge tools streamline the measurement process, reducing the time and effort required to assess structural components. This efficiency is particularly valuable in professional settings where time is a critical factor. By quickly and accurately identifying issues or verifying dimensions, technicians can expedite repair and modeling processes.

Furthermore, the use of a beam profile gauge tool contributes directly to the structural integrity of the vehicle. By ensuring that beams and frame components are within specified tolerances, you are directly enhancing the safety and longevity of the car. This is especially vital in classic car restoration, where maintaining original structural parameters is key to preserving the vehicle’s value and roadworthiness.

In car modeling, whether for restoration, customization, or performance enhancement, the applications of a beam profile gauge tool are extensive. It is essential for:

- Chassis Alignment: Verifying and correcting chassis straightness to ensure proper wheel alignment and handling.

- Frame Repair: Accurately assessing damage to frame rails and beams after collisions, guiding precise repair work.

- Custom Fabrication: In projects involving custom chassis or roll cage fabrication, ensuring dimensional accuracy and structural soundness.

- Vehicle Restoration: Matching original beam profiles in classic car restorations, maintaining authenticity and structural integrity.

- Performance Tuning: Analyzing chassis flex and beam deformation under stress in performance vehicles, informing modifications for improved handling.

Selecting the right beam profile gauge tool depends on the specific needs of your car modeling or repair projects. Factors to consider include the range of measurement, the type of beams you typically work with, and the desired level of precision. Investing in a quality beam profile gauge tool is an investment in the accuracy, efficiency, and structural integrity of your automotive endeavors.

In conclusion, the beam profile gauge tool is not just an accessory, but a fundamental instrument for achieving excellence in car modeling and repair. Its ability to deliver precise measurements, enhance efficiency, and ensure structural integrity makes it an invaluable tool for anyone serious about automotive craftsmanship. By integrating this tool into your practice, you are taking a significant step towards achieving unparalleled precision and quality in every project.