The landscape of automotive repair is constantly evolving, and one of the most exciting advancements is the rise of 3d Printed Car Tools. For years, I’ve been immersed in the world of 3D printing, and after extensive hands-on experience, particularly with the Maker’s Tool Works (MTW) Create Express printer, I can confidently say that 3D printing is transforming how we approach vehicle maintenance and customization. The ability to bring bespoke tools and parts to life right in your garage is no longer a futuristic fantasy but a tangible reality.

My journey with 3D printing began with a passion for robotics, where the ability to rapidly prototype and create custom parts was invaluable. However, the potential of 3D printing extends far beyond robotics. The automotive world stands to gain immensely from this technology, offering solutions for creating specialized 3D printed car tools that are either unavailable commercially or prohibitively expensive. Imagine designing and printing a custom jig, a unique socket adapter, or a perfectly fitted trim removal tool – all tailored to the specific needs of your vehicle and repair job. This level of customization and immediacy was previously unimaginable.

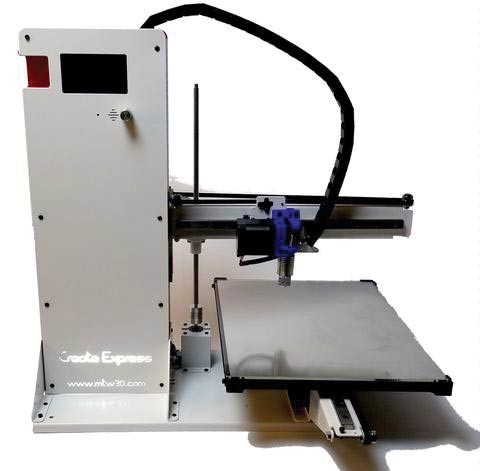

The MTW Create Express printer has been instrumental in realizing this vision. Since setting it up, it’s been running almost non-stop, churning out prototypes, parts, and yes, even a growing collection of incredibly useful 3D printed car tools. What sets this printer apart is its ease of assembly and user-friendliness. The often-steep learning curve associated with 3D printing is significantly reduced with the Create Express. It eliminates many of the initial setup headaches and software complexities that can deter newcomers.

Unleashing the Potential of 3D Printed Car Tools in Your Garage

The possibilities with 3D printed car tools are truly limitless. Websites like Thingiverse are treasure troves of downloadable designs, many of which can be adapted or directly used for automotive applications. From custom dashboard mounts for devices to specialized wrenches and clips, the online community is constantly contributing to the library of printable tools.

My own explorations have led to the creation of various automotive-related prints. While originally designed for robotics, sensor holders, for instance, can be repurposed as mounts for diagnostic sensors in cars. Similarly, the principles behind designing robust robot parts translate directly into creating durable and functional 3D printed car tools.

Creating these 3D printed car tools typically begins with Computer-Aided Design (CAD) software. While professional-grade CAD software can be expensive, there are numerous free or affordable options available for hobbyists and DIY enthusiasts. OpenSCAD, which I personally use, is a powerful, free, and open-source option, although it does have a learning curve. Other user-friendly options are also available, catering to different skill levels.

Once your 3D printed car tool design is complete in CAD, the next step is using slicing software. This software converts your 3D model into layers that the printer can understand and build upon. The resulting file, often in .stl format, is then fed into the printer control software. Popular slicing programs like Slic3r and Cura are readily available and compatible with most 3D printers.

For controlling the printer itself, software like Pronterface or Printrun are excellent open-source choices. The MTW Create Express comes bundled with MatterControl software from MatterHackers, which integrates slicing and printer control into one seamless package. This simplifies the workflow, especially for beginners, as you don’t need to switch between multiple programs. MatterControl also allows for the use of other slicers if desired, providing flexibility and customization.

Setting up the firmware and fine-tuning printer settings used to be a significant hurdle in 3D printing. However, the MTW Create Express significantly simplifies this process. Unlike older printer kits that required extensive tweaking and lacked proper documentation, the Create Express is remarkably user-friendly right out of the box. This ease of setup is crucial for anyone wanting to focus on creating 3D printed car tools without getting bogged down in technical complexities.

The MTW Create Express: A Robust Platform for 3D Printed Car Tools

One of the standout features of the MTW Create Express, particularly for creating 3D printed car tools, is its large print area. Despite its relatively compact footprint, the printer maximizes the usable print volume, offering a substantial 250 x 315 x 250 mm build space. This generous size allows for printing larger tools or multiple smaller tools in a single run, increasing efficiency and productivity in your garage workshop.

The printer’s precision and print quality are equally impressive. The inclusion of an ANTCLABS BLTouch auto bed leveling unit ensures consistent and even prints across the entire build platform, critical for functional and accurate 3D printed car tools. Features like the E3D-V6 hot end and direct drive extruder further contribute to the printer’s reliability and ability to handle various printing materials suitable for tool creation.

The MTW Create Express also boasts a quiet operation thanks to its use of recirculating ball linear rails instead of traditional steel rods for axis movement. This quietness is a welcome feature, especially for longer prints, and ensures a more pleasant workshop environment. The Einsy Rambo 3D printer controller and Trinamic stepper drivers further enhance precision and minimize noise. The printer comes pre-configured with Marlin firmware, eliminating the need for complex firmware adjustments and allowing for immediate use.

The graphic LCD card with SD card support provides convenient standalone operation, and the option to upgrade to wireless control via Wi-Fi adds further flexibility. This connectivity allows for remote monitoring and control, streamlining the workflow for busy automotive enthusiasts.

Support and Resources for Your 3D Printing Journey

Maker’s Tool Works and MatterHackers provide comprehensive support resources to assist users at every stage, from assembly to operation and tool design. The Maker’s Tool Works website (makerstoolworks.com) offers detailed documentation on printer assembly and software, along with a live chat feature for quick assistance. Their Facebook page serves as a community forum for sharing tips, asking questions, and showcasing 3D printed creations, including 3D printed car tools.

MatterHackers (matterhackers.com), the developers of MatterControl software, also offer extensive documentation and a blog with helpful articles and tutorials. Their Facebook page provides another avenue for community support and inspiration.

Conclusion: 3D Printing – The Future of Car Tools

Assembling the MTW Create Express was a straightforward experience, with readily available support to overcome any minor hurdles. The printer’s performance has been consistently exceptional, delivering high-quality prints with minimal adjustments. Its reliability and ease of use make it an ideal tool for anyone venturing into the world of 3D printed car tools.

The MTW Create Express has become an indispensable part of my workshop, running continuously and producing a wide range of functional and customized items. Its ability to create bespoke 3D printed car tools opens up new possibilities for automotive repair, customization, and problem-solving. Whether you’re a seasoned mechanic or a DIY car enthusiast, exploring the potential of 3D printed car tools with a printer like the MTW Create Express is a game-changer. It empowers you to create the perfect tool for any job, precisely when you need it, revolutionizing your approach to auto repair and maintenance.