Are you dreaming of creating your own line of hair care products, starting with shampoo? Do you aspire to transform your homemade recipes into a recognized brand? Are you concerned about the challenges entrepreneurs face when choosing the wrong equipment?

Consider this your comprehensive guide to Hair Care Materials And Tools for shampoo production!

In this article, we will explore the fundamental hair care materials used by shampoo manufacturers and the essential production tools necessary for your hair care business.

Understanding the Hair Care Market: Shampoo Niche

The demand for hygiene products, particularly shampoos, has surged dramatically due to the increased focus on cleanliness and hygiene.

Global market analysis indicates that the shampoo market is projected to reach USD 1.48 billion by 2024, with an impressive CAGR of 9%. This growth highlights the significant opportunity for entrepreneurs venturing into shampoo production and sales. To capitalize on this market, you need to develop effective shampoo formulations and invest in appropriate hair care production tools.

Let’s begin by examining the core hair care materials required for formulating shampoo.

Key Hair Care Materials: Shampoo Ingredients

While the shampoo aisle in your local store offers a vast array of brands, the truth is that most shampoos share a common set of base ingredients.

As beauty expert Paula Begoun from Beautypedia notes, “All shampoo is essentially a cleanser.” She further emphasizes, “Only the first five or six ingredients impact the formula’s effectiveness.”

Comparing the ingredient lists of various shampoos reveals a significant overlap, with approximately 10 ingredients forming the foundation of most formulations.

Here are the most prevalent hair care materials found in standard commercial shampoo recipes:

1. Deionized Water/Water

Water is the most abundant ingredient in shampoo, typically constituting around 80% of the formulation. Serving as a solvent, water, or aqua, is crucial for ensuring the liquid consistency necessary for lathering and dispensing from the bottle.

2. Surfactants (Sodium Lauryl sulfates)

Surfactants are essential hair care materials that act as detergents. They work to remove dirt and oil from the hair surface, allowing them to be washed away during rinsing. These ingredients are responsible for the “squeaky clean” feeling and are also key components in soaps, contributing to lather formation.

3. Foaming Agent (Cocamidopropyl Betaine)

Cocamidopropyl Betaine is a common foaming agent used in many shampoo formulations. It enhances lather production and also contributes to thickening the shampoo, improving its viscosity. Additionally, it provides mild cleansing and conditioning properties, enhancing the overall hair washing experience and contributing to softer hair.

4. Conditioning Polymers (Polyquaternium)

Frequently utilized in the personal care industry, conditioning polymers like Polyquaternium are vital hair care materials. They form a protective film on the hair shaft, reducing static and improving manageability. This results in smoother, less tangled hair after washing.

5. Preservatives (Parabens)

Parabens are widely used preservatives in cosmetics and personal care products, including shampoos. They prevent bacterial growth, ensuring product safety and longevity. While concerns exist about certain parabens and their potential estrogenic effects, they are used in minute quantities in shampoos to minimize any risk.

6. Opacifying Pearling Agents

The glossy, pearlescent appearance of many shampoos is achieved through opacifying pearling agents. These materials not only thicken the shampoo but also reduce transparency, giving it a silky, white, and appealing look.

7. Conditioning Emollients (Dimethicone)

Dimethicone is a prevalent conditioning emollient in shampoo formulations. As a key hair care material, it provides moisturizing benefits, conditions the hair, and imparts a smoother, softer feel. Emollients are crucial for counteracting the drying effects of surfactants.

8. PH Adjuster (Citric Acid)

Citric acid, often listed as sodium citrate, is a common pH adjuster in shampoos. Maintaining the correct acidity level, typically around pH 5.5 or lower, is crucial for hair health. The acidic pH helps to smooth the hair cuticle, resulting in shinier and healthier-looking hair.

9. Salt (Sodium Chloride)

Sodium chloride, or common salt, is used in shampoo formulations to increase viscosity and enhance the perceived fullness of hair. It works by slightly roughening the hair cuticle, which can add volume.

10. Fatty Alcohols

Despite the common perception of alcohols as drying, fatty alcohols are beneficial hair care materials that act as moisturizers. Ingredients like Panthenol, Cetyl Alcohol, Stearyl Alcohol, and Cetearyl Alcohol are fatty alcohols found in many cosmetic creams and shampoos. They help to bind water to the scalp and hair, providing hydration. Panthenol, specifically, is a fatty alcohol that delivers vitamin B5.

Typical Shampoo Composition

The following table outlines typical hair care raw materials used in shampoo production, along with common variations and their usual percentages in a formulation. These components, while having variations, generally serve the same functions in shampoo.

| Hair Care Material Category | Variations in Shampoo Label | Percentage in the Solution |

|---|---|---|

| Water | Aqua, Deionized Water | 73-90% |

| Surfactant | Sodium/Ammonium Lauryl sulfates | 8-15% active |

| Foaming Agents | Cocamide or Cocamidopropyl Betaine, Lauryl/Coco Hydroxypropyl Sultaine, Disodium Cocoamphodiacetate, Cocamide MEA, and Decyl Glucoside | 2-6% active |

| Conditioning polymers | Guar Hydroxypropyltrimonium Chloride (the most popular), Polyquaternium 10, Polyquaternium 6, and Polyquaternium 7 | 0-1% |

| Preservatives | Methyl and propyl paraben, formaldehyde, Quaternium-15 | 0.001-1% |

| Opacifying Pearling Agents | Alkanolamides of higher fatty acids, propylene glycol, Mg, Ca and Zn salts of stearic acid, spermaceti, etc; Glycol Stearate | 0-1% active |

| Conditioning emollients | Typically Silicone or other minerals such as Lanolin, mineral oil, herbal extracts, egg derivatives | 0-1% |

| pH Adjuster | Citric acid | Proper quantity |

| Salt | Sodium Chloride | 0-2% |

| Fatty Alcohol | Panthenol, Cetyl Alcohol, Stearyl Alcohol or Cetearyl Alcohol | 4-5% |

Note: For sourcing hair care raw materials for your shampoo business, online platforms like Making Cosmetics, Grapefruit, and Amazon are excellent resources.

For bulk purchases at potentially lower costs, consider Alibaba or Indiamart. However, bulk buying typically involves Minimum Order Quantities (MOQs). Beginners may find it more manageable to start with smaller quantities.

While the market may seem saturated with numerous shampoo brands and formulations, it’s important to recognize that the core ingredients remain consistent. Variations primarily lie in fragrances and specific functional additives for concerns like dandruff or hair loss.

This leads us to the crucial question: how can you develop your own shampoo recipe, especially if you lack formulation experience?

Developing Shampoo Formulations

Many homemade shampoo recipes are available online, but discerning legitimate and effective formulations is essential.

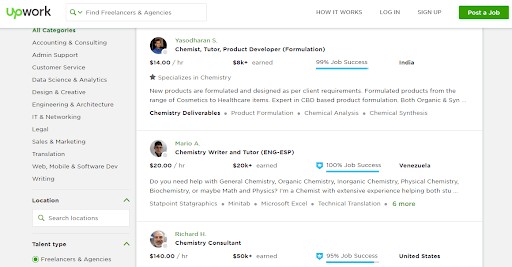

If you have a background in chemistry, formulating shampoo might be straightforward. If not, hiring a chemist is a viable option. Freelancing platforms like Upwork offer access to chemists who specialize in cosmetic formulations, including shampoos.

Hiring a freelance chemist for shampoo formulation typically costs between $1000 and $1500 per formulation.

Formulating Shampoo Based on DIY Recipes

Creating your own formulations from homemade recipes is possible, provided you conduct thorough research and implement product testing. While specific regulatory standards for shampoos before market entry are not universally mandated, cosmetic industry associations in regions like America and Europe recommend stability testing for manufacturers.

For specialized shampoos, such as anti-dandruff or medicated formulations, rigorous third-party testing is crucial, particularly in regions like the US where they are regulated as Over-The-Counter (OTC) drugs. For any shampoo line, stability testing is a prudent step to ensure product safety and consumer confidence.

Essential Hair Care Production Tools: Equipment for Shampoo Manufacturing

Common questions for those starting shampoo production include: “Can I use a kitchen blender for mixing shampoo?”, “Is specialized mixing equipment necessary?”, “What is the cost of shampoo mixing equipment?”, and “Do I need automated filling and sealing machines?”

For effective shampoo manufacturing, investing in appropriate hair care production tools is highly recommended. A standard shampoo production line includes:

- Mixing Equipment

- Packaging Equipment

- Filling Equipment

- Automatic Sealing Equipment

- Labeling Equipment

Shampoo Mixing Equipment

A Shampoo Mixer is the central tool where the mixing process occurs. These industrial-grade blenders are designed to produce stable emulsions, which are critical for shampoo quality.

A typical shampoo mixer features a rotor-stator workhead, a slow-speed stirrer, a disperser, a motor, and a transmission mount. Optional features include automated lifting systems, powder feeders, suction pumps, load cells, and heating elements.

Load cells are particularly beneficial as they automatically measure the precise quantities of hair care materials added during each batch, eliminating the need for separate weighing.

Investing in quality mixing equipment enhances product homogeneity and overall manufacturing quality, contributing to a positive brand reputation.

Household kitchen blenders or food processors are not suitable for shampoo production. Industrial mixers are specifically engineered with rotor-stator homogenizers and slow-speed agitators with scrapers, optimized for processing hair care materials. Dispersers, or saw-tooth impellers, are used for effectively dispersing powders into liquids.

This type of mixing equipment is also essential for manufacturing a range of cosmetic and personal care products including cosmetics, creams, lipstick, nail polish, mayonnaise, hand sanitizer, toothpaste, and more.

Filling Equipment

Large-scale hair care product manufacturers typically use automated filling machines to ensure precise and efficient shampoo bottling. These machines utilize servo-motors and pneumatic systems to control liquid dispensing into bottles.

Shampoo filling machines are particularly crucial for mid-to-large-scale operations aiming to produce high volumes of inventory. The investment ranges from approximately $8,000 to $25,000 when sourced from Chinese manufacturers.

Sealing Equipment

Automated Sealing Machines are used for efficiently capping shampoo bottles in large production settings. These machines ensure consistent and secure bottle closure, operating at speeds of 40 to 100 bottles per minute.

PLC programs in capping machines allow for easy adjustments of parameters like capping speed and bottle size changeovers. Adjustable roller heads accommodate various bottle cap dimensions.

A Shampoo Capping Machine typically costs between $5,000 and $10,000 per set.

Labeling Machines

Effective shampoo labeling and branding are as critical as formulation and mixing quality. Labels communicate product benefits and brand identity, influencing consumer purchasing decisions.

Automatic labeling machines apply labels to both the cap and container at high speeds, capable of processing over a thousand units daily. These are recommended for businesses with sales volumes exceeding manual packaging capacity. Labeling machines usually cost between $5000 and $10,000 per set.

Starting Shampoo Production on a Budget

For entrepreneurs starting with limited capital, cost-effective solutions are available. Lab mixers from manufacturers in China offer a more accessible entry point.

Laboratory/Overhead Mixers: Affordable Mixing Tools

Laboratory or Overhead mixers are high-shear, stainless steel mixers designed for small-scale production and testing of cosmetics and personal care products like shampoos. Load cell options are available, eliminating the need for separate ingredient weighing.

Sourced from Chinese manufacturers, these mixers range from approximately $300 to $7,000 per unit, depending on specifications and features. Utilizing a high-shear lab mixer for small-scale shampoo production offers advantages such as:

- Ingredient testing for emulsion stability.

- Market testing with small product batches.

- Consistent product mixing at a lower cost while maintaining quality.

- Using appropriate tools for emulsion creation.

Packaging Equipment for Startups

Initially, you can forego automated filling and sealing machines. Manual filling of screw-cap bottles and hand-applying labels are viable for startups.

However, as your business grows and production scales up, investing in larger mixing tanks or batch mixers, along with filling, sealing, and labeling machines, will become necessary.

Testing Your Shampoo Product

Regardless of whether you formulate shampoo yourself or hire a chemist, thorough product testing is crucial for ensuring quality and safety. Shampoo formulations must be safe for consumer use.

Many manufacturers utilize third-party testing facilities. However, preliminary in-house testing can save time and costs before engaging external labs. Passing relevant tests minimizes the risk of potential legal issues.

Common tests for shampoos and cosmetics include Stability Tests, Microbiological Tests, and Packaging Stability Tests.

Essential Testing Tools

For in-house testing, you will need basic tools such as:

- Digital Scale

- Incubator (-10 to 50°C range)

- Viscometer

- Microbial Test Kit (available commercially, e.g., from Formulator Sample Shop).

Stability Testing

Stability testing assesses product behavior under varying environmental conditions. It involves chemical, physical, and integrity evaluations, examining aspects like color, viscosity, flow, fragrance, pH, texture, and emulsion stability.

Accelerated Stability Testing, a type of physical stability test, evaluates shelf life under controlled temperature and humidity. This requires an Incubator to maintain samples at 37°C, 40°C, or 45°C for up to 3 months.

Microbiological Testing

Microbiological Tests evaluate the product’s resistance to microbial growth during its use. User-friendly microbial testing kits are available, simplifying sampling and assessment even without specialized training.

Packaging Stability Testing

Packaging stability testing assesses the container’s impact on the product and the product’s integrity once opened to the environment.

Conclusion

Producing and successfully marketing shampoo involves a complex journey from formulation and material sourcing to mixing, packaging, and testing. This guide aims to clarify the essential hair care materials and tools needed for shampoo production.

Ginhong, as a leading shampoo mixer manufacturer in China, offers professional cosmetic production equipment. If you are ready to launch your shampoo business, contact us to discuss your needs and receive expert advice on mixer specifications.

LET’S TALK!